Our finishes

Our goal is to help you identify and apply the right colors, textures and designs to your anodized aluminum product.

You have a range of choices:

• Clear

• Champagne

• Light bronze

• Architectural bronze

• Black

How to select the anodic finish for your products.

Anodizing aluminum renders it more resistant to wear, corrosion and heat, and enhances its appearance. We can deliver your anodized aluminum product in a clear, champagne, light bronze, architectural bronze or black finish.

*These colors are shown for information purposes only.

Contact us to order a physical sample.

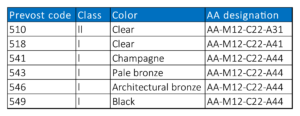

Classes of anodic finishes

Classes of anodic finishes and criteria are developed by the American Architectural Manufacturers Association (AAMA). Class I finishes are high-performance anodic finishes used in exterior applications receiving periodic maintenance, such as curtain walls.

Class II finishes are commercial anodic coatings used in interior or exterior applications receiving regularly scheduled cleaning and maintenance, such as storefronts.

Care and maintenance

Anodized architectural aluminum requires attention before, during and after its installation. Although anodized aluminum is a resilient finish, harsh chemicals, abuse and neglect can lead to the loss of its initial beauty. Prior to the installation, it is important to store the material in a dry clean and secure place. Any wet packaging materials, wood or cardboard, should be removed immediately to avoid staining from the chemicals that may be released from these packing items. Cement, plaster, terrazzo and alkaline and/or acid-based materials used to clean masonry are very damaging to the anodized finish and should be avoided at all costs. Any such products that may come in contact with the finish should be removed with water and a mild soap immediately to prevent any permanent staining. Staining due to these products is virtually impossible to remove or repair and will result in the need to replace or reanodize the product in question. Therefore, during construction, it is recommended to let other trades finish their installation first.

All surfaces that are exposed to the atmosphere collect soil and dirt, depending on their geographic area, environmental conditions and the location of the building. Such conditions usually affect only the surface finish and do not reduce the life of the aluminum. These factors and the building owners’ attitude regarding appearance determine the type and frequency of cleaning required. Generally speaking, the maintenance schedule is as follows: For rural areas, at least once every three years; For urban locations, at least once a year; and for industrial and marine environments, every six months.

Cleaning methods (in order of increasing severity)

1) Wash with clean warm water and dry with a soft cloth.

2) Wash with a mild soap or non alkaline detergent and water with a stiff brush; rinse and dry with a soft cloth.

3) Wash with water and the aid of a pressure washer, carefully so not to damage gaskets and / or caulk joints, dry with a soft cloth.

4) Wash with water and a mild abrasive powder with or without a detergent additive. Products like pumice powder or off the shelf cleaners such as “Ajax”, “Vim” or “Old Dutch” will work. Apply with a cloth and rub in a uniform direction and manner. Rinse well with clear water and dry with a soft cloth.

5) If there are non-water soluble deposits it may be necessary to use a solvent cleaner such as alcohol, mineral spirits, xytol, MEK or acetone. A test area should always be cleaned first to assure the desired results. Caution should be taken to avoid damage to gaskets and caulk joints. After any such cleaning a final wash with soap and water is always recommended.

If none of the above procedures give an acceptable result there are professional companies who have more aggressive methods to restore the beauty of the anodized aluminum.

An infinite selection of coating colours

We can also deliver your product in a wide range of colours and finishes, using the finest powder coats and enamels in the business—coatings specifically designed for the architectural and construction industry.

You have a project ?

We can help you make the right choices regarding architectural aluminum building envelope solutions.